Description

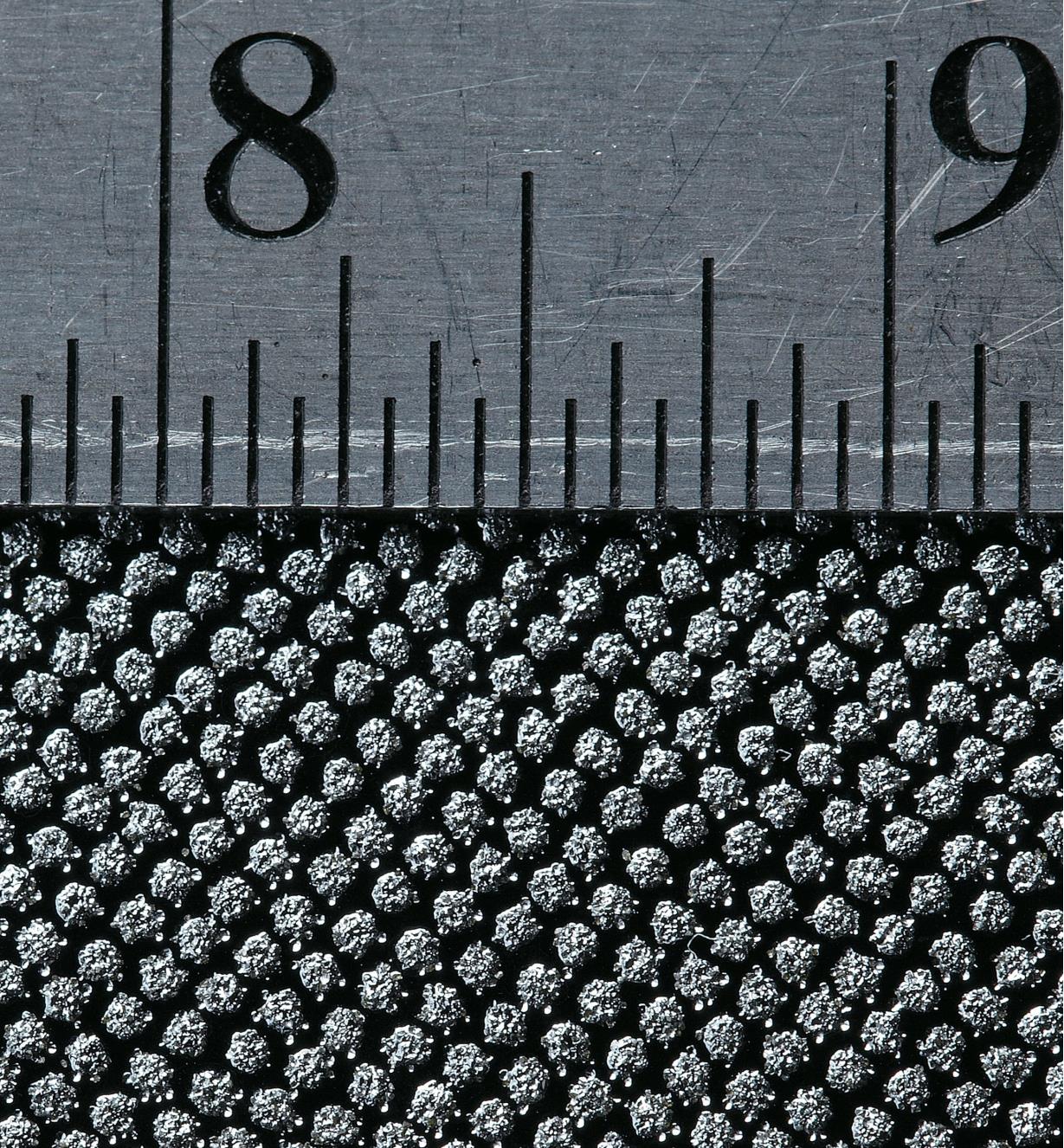

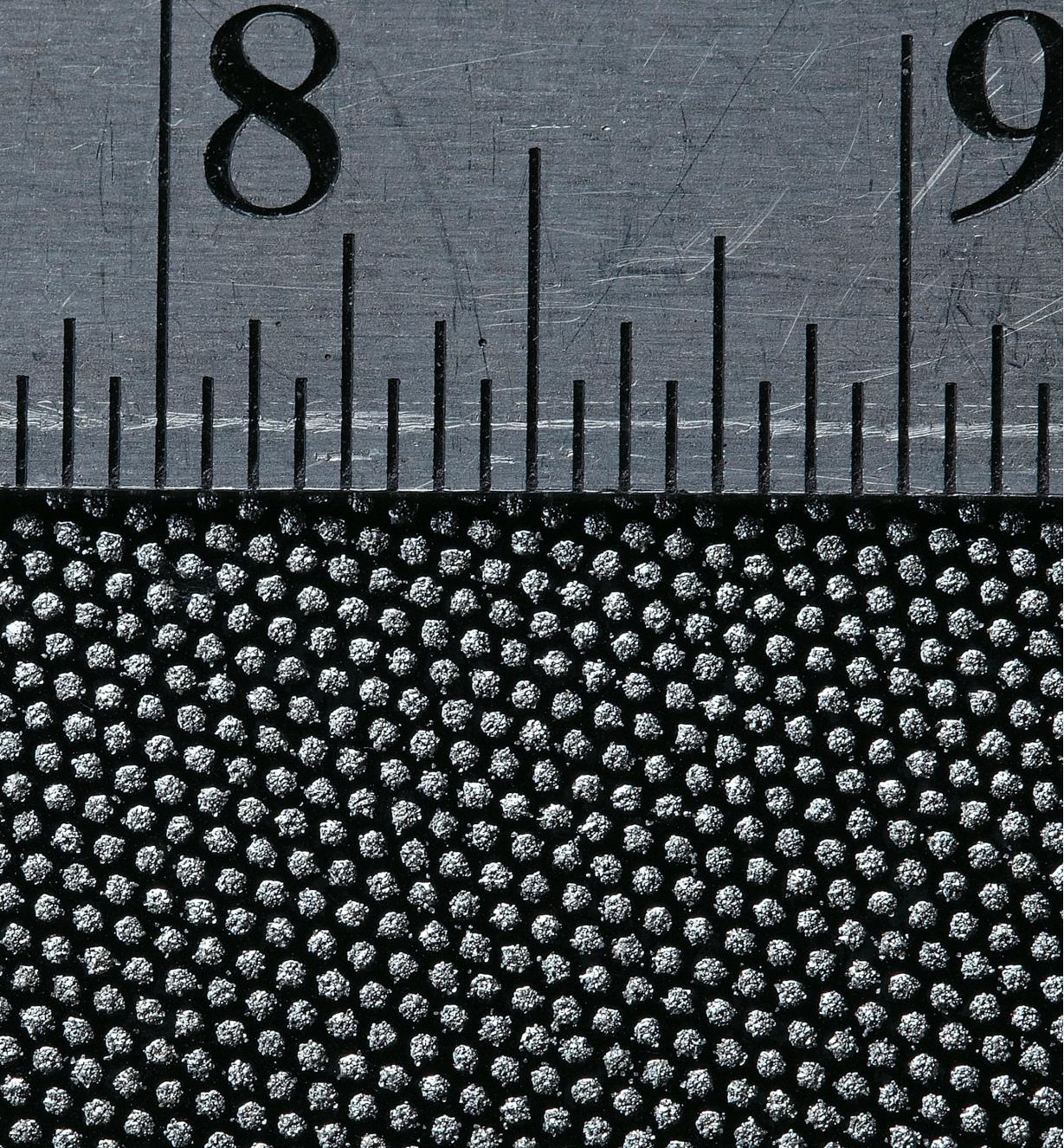

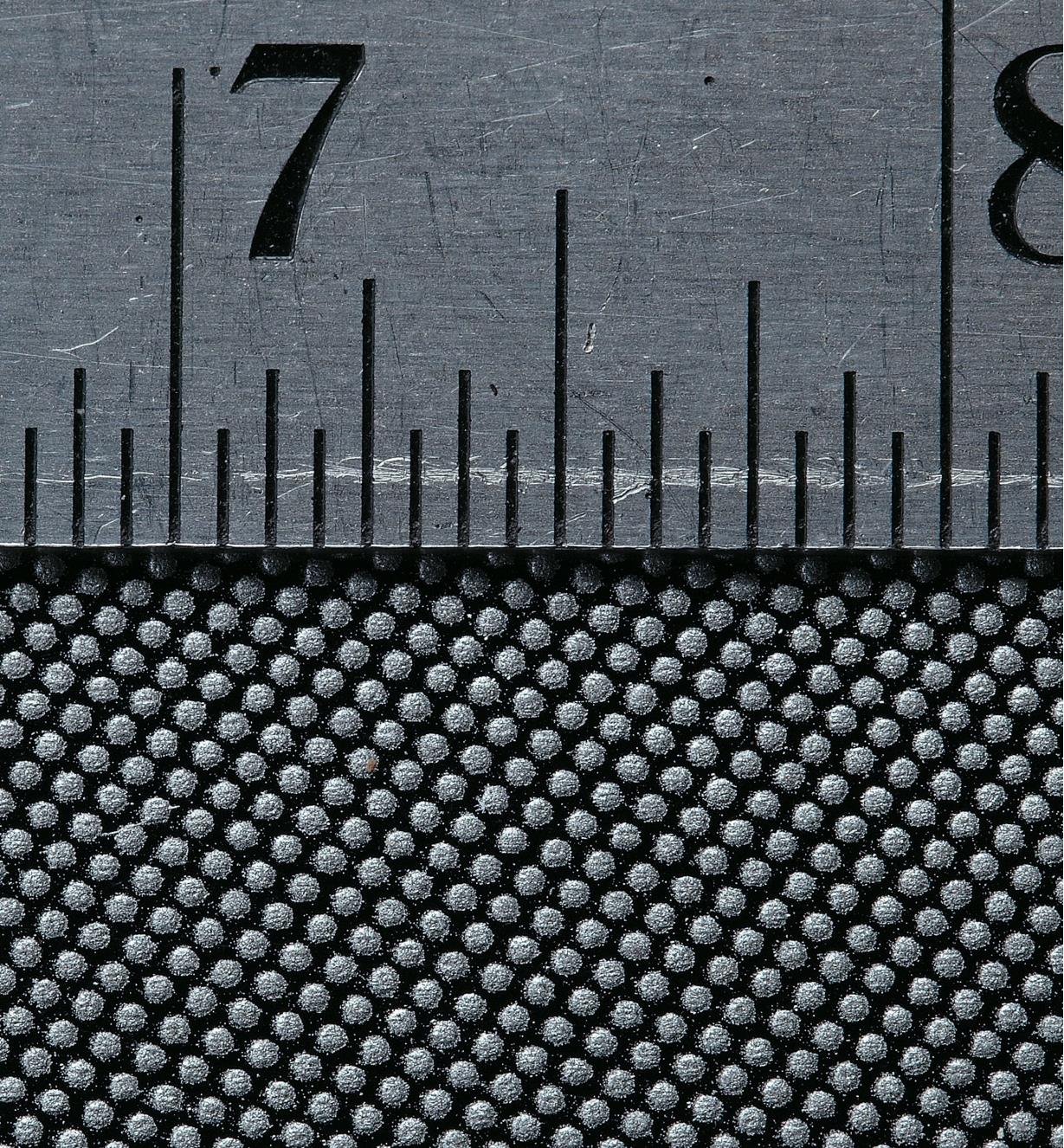

In spite of their impressive qualities, these plates are little-known outside Japan. Instead of being distributed evenly, the monocrystalline diamonds are arranged in clusters, which abrade more aggressively than individual particles. This, coupled with their high fracture resistance, yields a surface that cuts quickly, wears slowly and produces a consistent scratch pattern. Swarf collects in the channels around the clusters, minimizing loading and hydraulic lock.

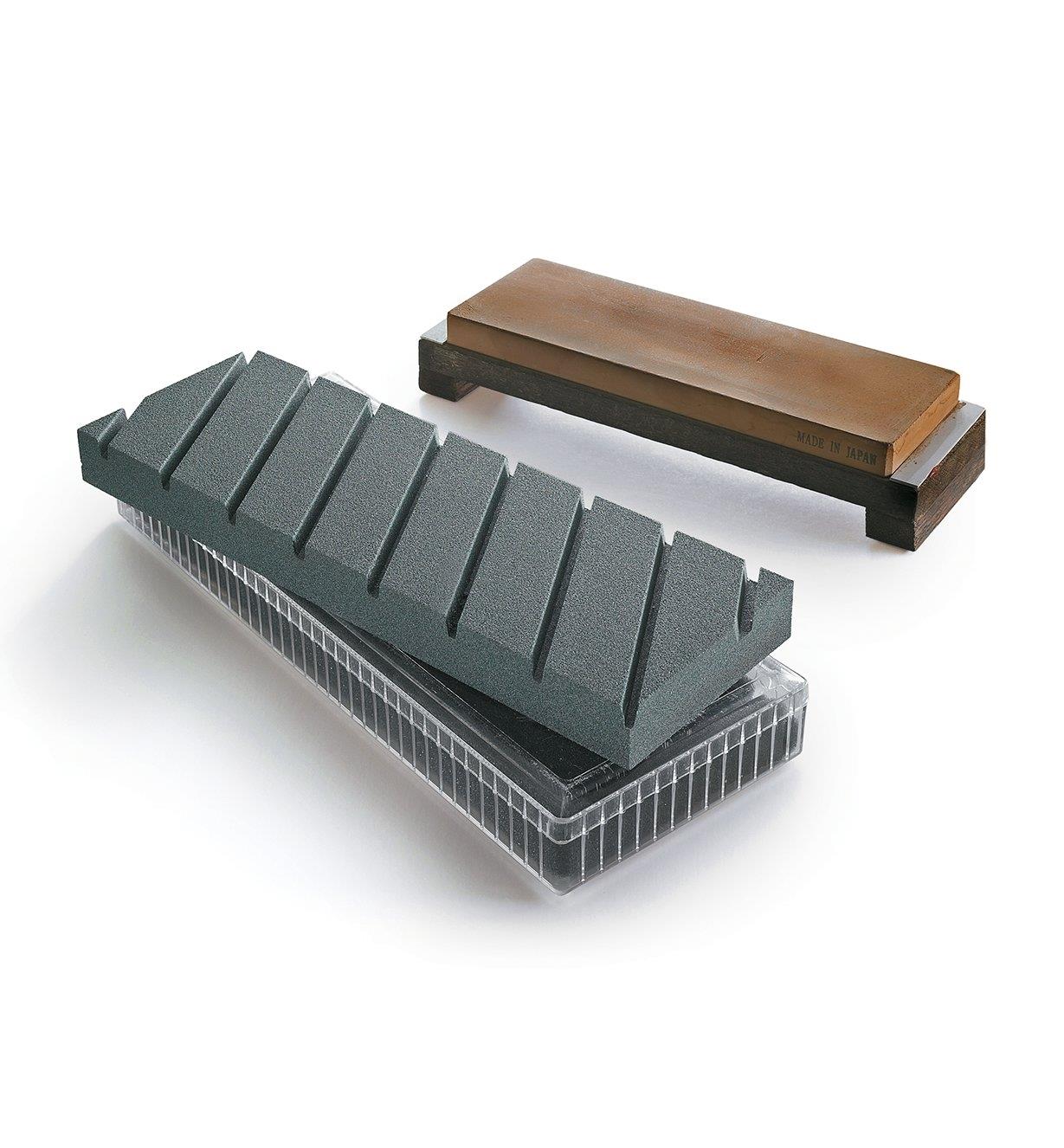

The plates can be flushed with water when used on steel, but we found a light oil preferable. The diamonds of the 140x and 400x are electro-bonded to a steel sheet (the 1200x is electro-bonded to a stainless-steel sheet) that is mounted to a 10mm thick aluminum block, for an overall flatness of ±0.04mm. This construction makes the plates durable, rust resistant and reliable for lapping.

The 140x is for rapid material removal; the 400x is suitable for fast lapping, truing water stones or shaping a primary bevel; the 1200x can be used for fine lapping or general sharpening, and leaves a toothed edge on kitchen knives. All are 75mm wide by 210mm long (approximately 3" × 8 1/4").

Replacement diamond abrasive sheets are available separately.