Description

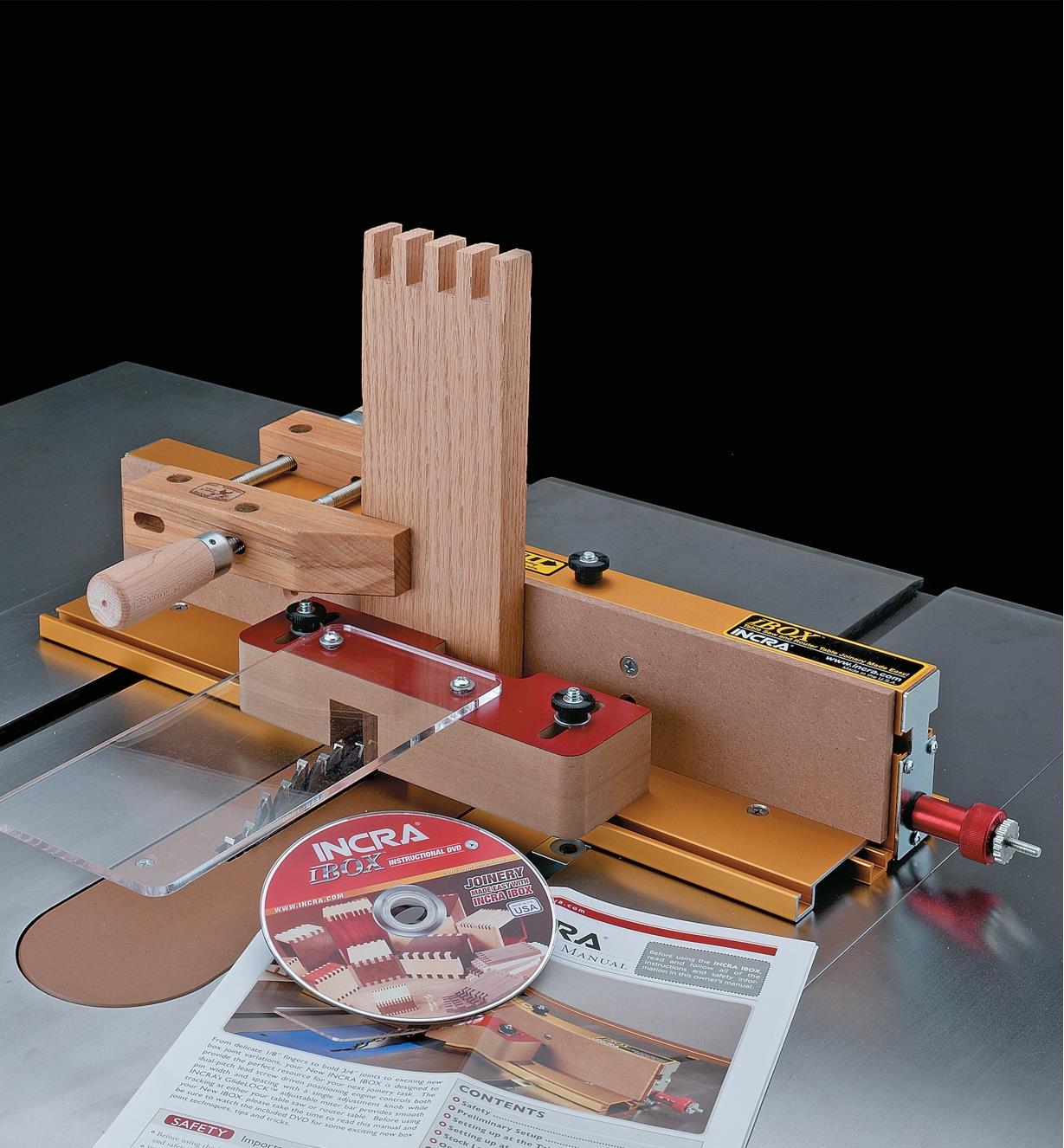

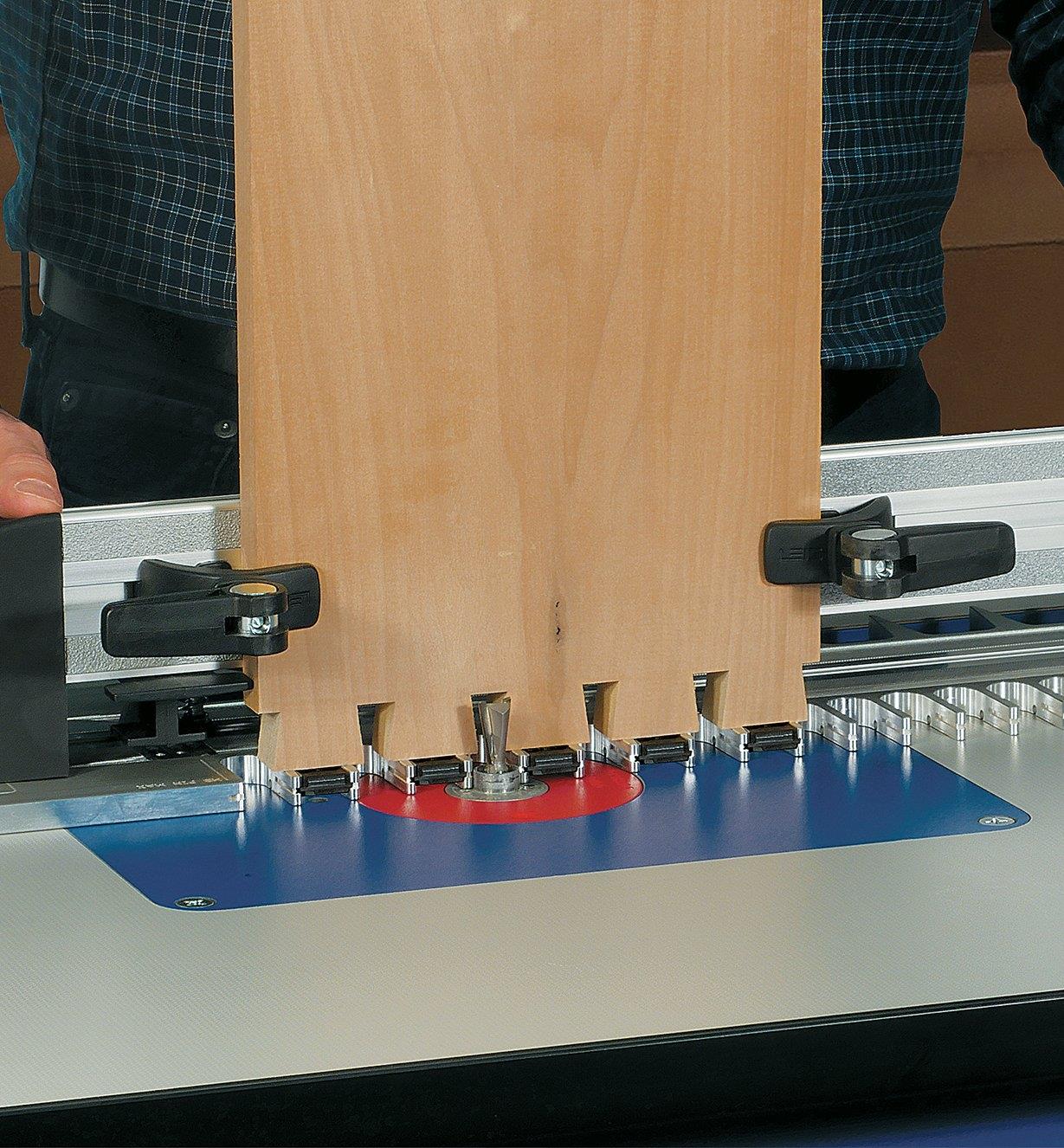

One of the challenges of using a typical finger joint jig (commercial or shop-made) is properly setting the distance between the cutter and indexing pins. The accuracy of this relationship is critical, since it is what determines the fit of the joint. If spaced too widely, the joint will be overtight; too close and you'll have gaps. That's what sets this jig apart.

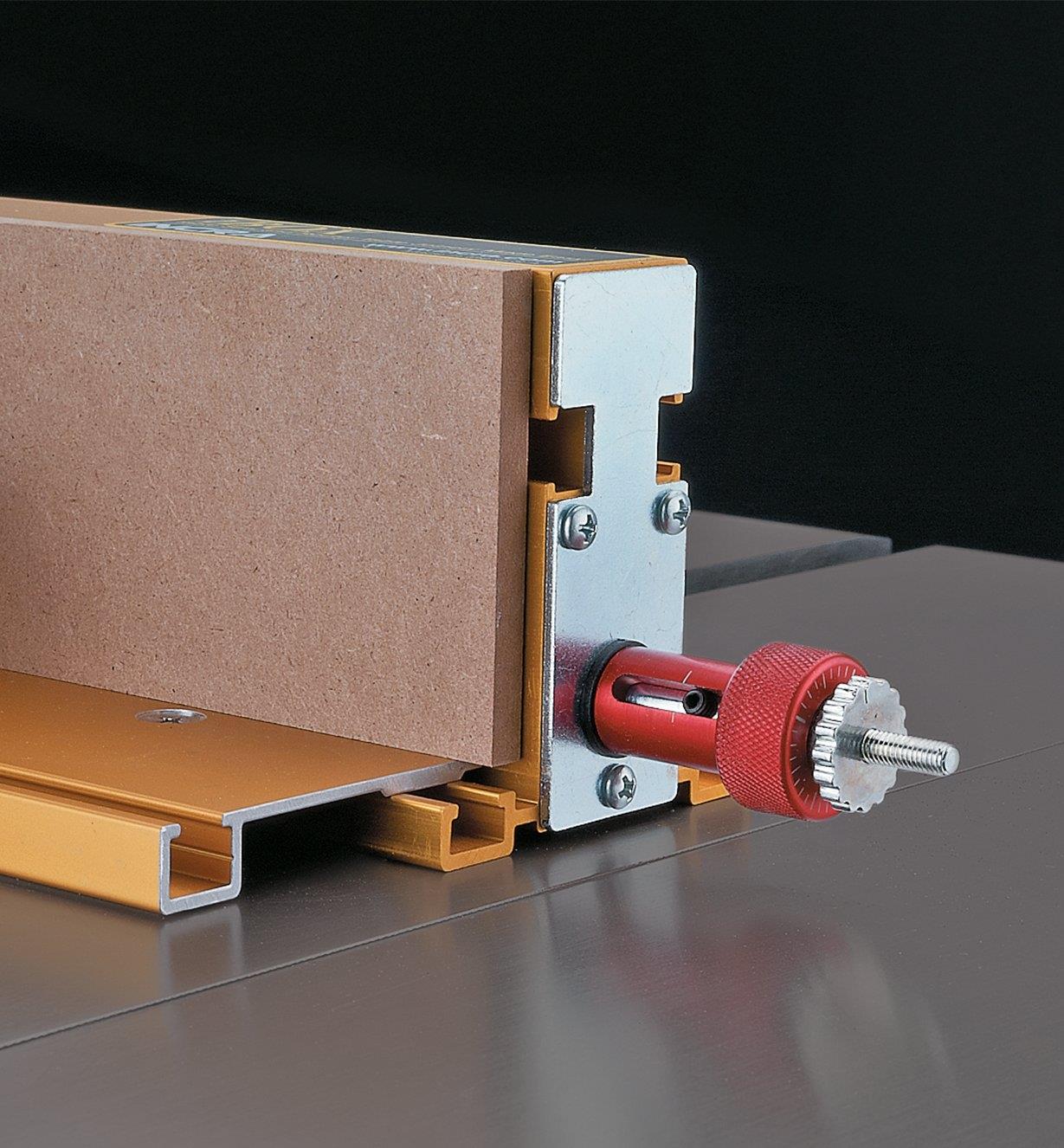

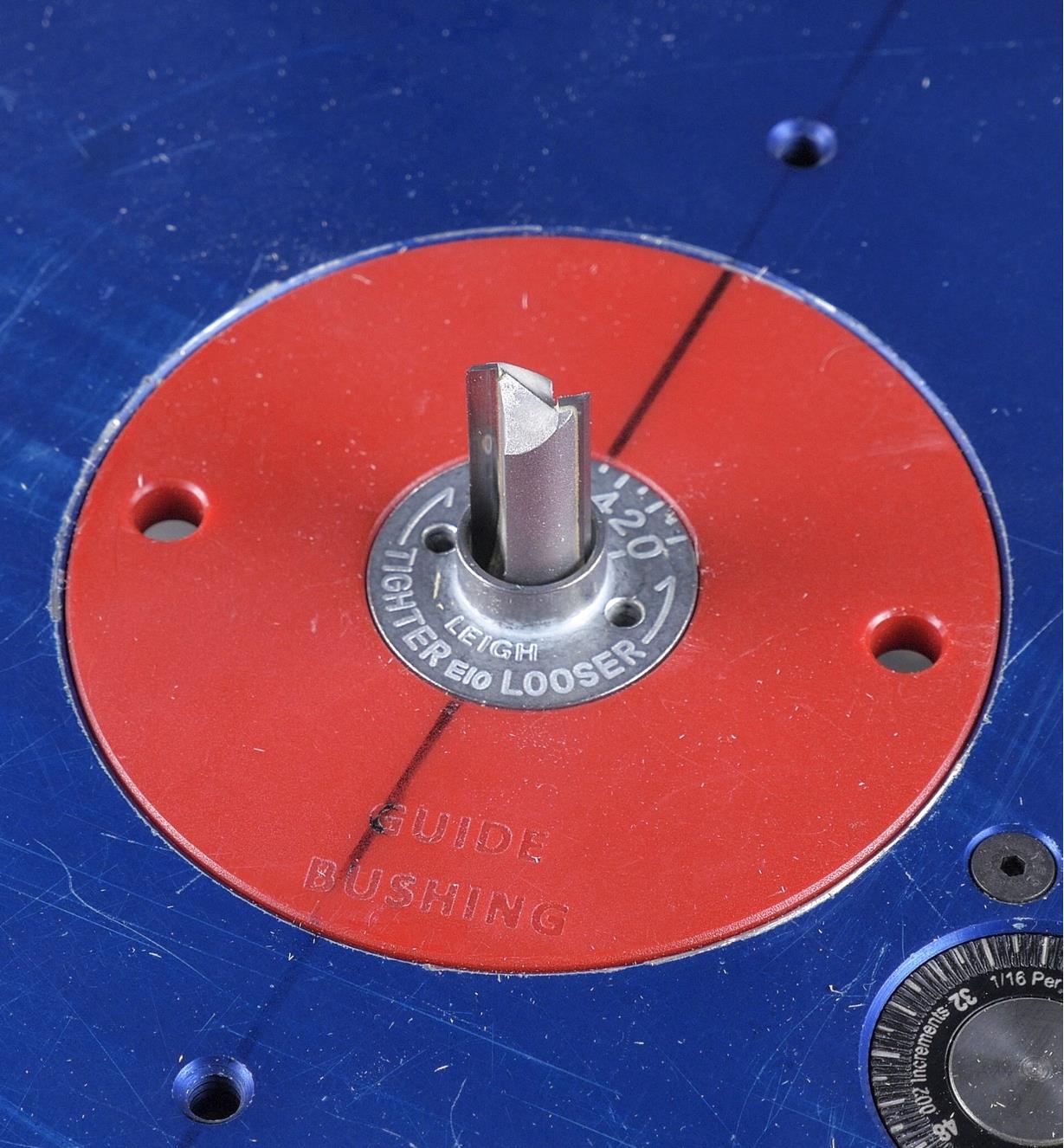

Designed both as a work carrier and as a precision template, it has a special pin plate micrometer to make registration with the blade and pin width adjustment quick, simple and accurate. One knob zeroes the template against the blade, and the other adjusts the width of the pin plates to fit a notch you cut in a test piece with your blade. To ensure accurate positioning, the dual-pitch lead screw of the micrometer moves the two indexing pins in phase with each other and relative to the cutter. No measuring or trial-and-error fitting is required.

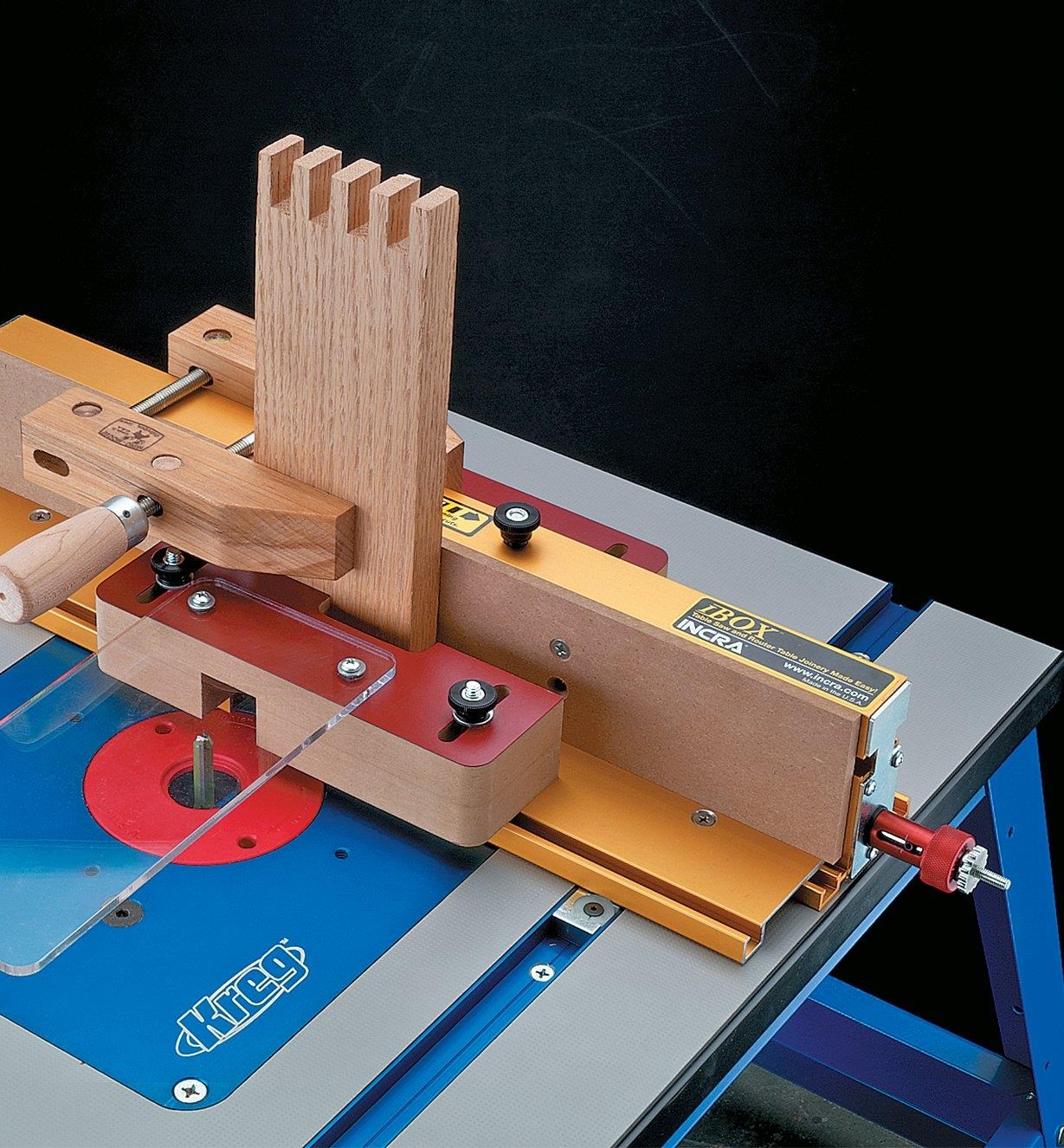

Suitable for stock from 1/8" to 1 1/4" thick and pin widths from 1/8” to 3/4", the jig is largely aluminum, with front and rear MDF blade guards (the front guard doubles as a stock support) and a cantilevered polycarbonate shield to deflect debris from the operator. A U-shaped cutout on the front guard lets you see the indexing pins as you adjust the stock for the next cut. The leading split-ledge provides stock support on both sides of the cut, and is adjustable for cut width and pin placement.

The MDF subfence reduces tear-out, and is reversible and replaceable. For use on table saws or router tables with a standard 3/8" × 3/4" miter groove, it can be used on left- or right-tilting saws. An excellent jig for making symmetric, keyed or splined box joints, it can also be used to make dentil molding for furniture accents.

Made in USA.

Not available for shipment to Québec.